Custom PCB Design and Manufacturing

Turn-key embedded product creation - from zero to hero

Need a fully custom embedded solution made from scratch? Not a problem! We’ll handle the whole process – from componen selection, to diagram, PCB layout, board routing, to production and testing. We’ll create a new, shiny board that’s tailored to your exact needs and delivered to your door. That includes the most complex products with analog signal processing and high speed IO, fit for aerospace, automotive or industrial uses. Send us a message, and let’s see what we can do for you!

Develop your existing project

Do you have a custom project you’d like to upgrade or maintain? Or maybe you’re stuck in development of your dream solution, and searching for someone to put it back on track? Get in touch! We’re experienced in working with the most demanding client solutions and resolving the most complex issues.

Bring us what you have. We’ll take it from there to deliver an impeccable, world-class quality product that will drive your business forward for the years to come. Contact us, and let’s push your project forward!

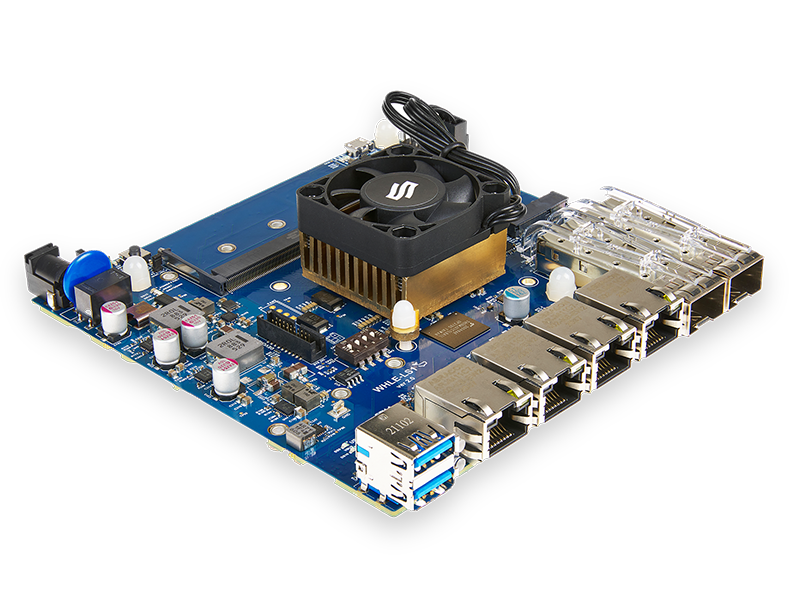

Customize a board

Do you like one of our products, but absolutely need a feature? Not an issue! We fully own our designs, and we can customize them to deliver anything you need.

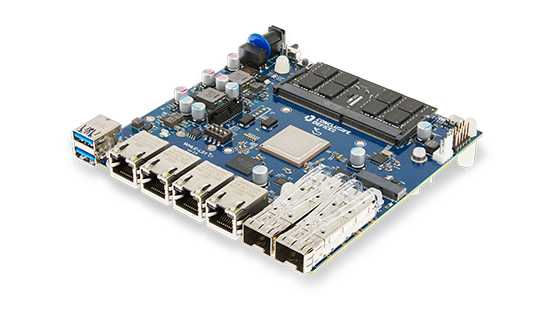

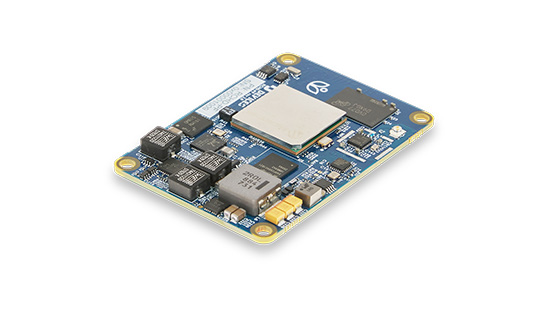

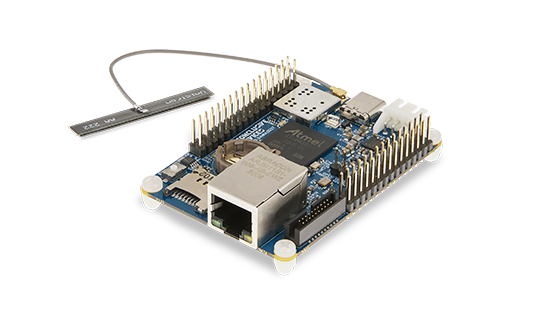

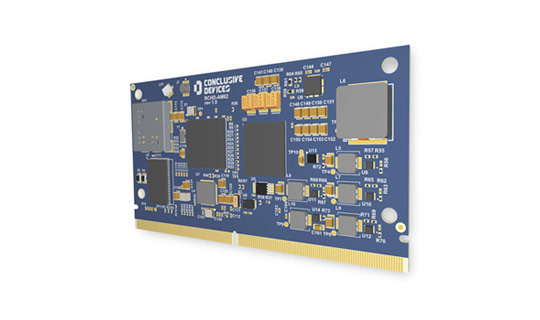

Would you like to shrink the WHLE, give RCHD-PF a rack-wide IO panel with Infiniband or optic fiber, or add a CAN bus if it’s not there? Or maybe you need a variant for automotive temperature range, or radiation hardening? The possibilities are endless! We design our products with extensive customization in mind, so they’re very flexible – from chip to RAM, from board dimensions to power sections. Pick, choose, and get in touch!

Professional service

Practice makes perfect. Our perfection was forged by delivering hardware-embedded solutions to top global clients for over a decade.

Looking for a one-stop-shop to provide you with a full design and manufacturing embedded hardware pipeline, from concept to market? You've come to the right place.

Development and production

Our development and production pipelines assure full confidentiality of the intellectual property and integrity of the product during design and production stages. If your product has anti-tamper and reverse-engineering prevention features, we can activate them early to ensure security in transit and operation. Your hardware - your fortress.

Creating hardware solutions is our domain

Each and every software stack requires a solid hardware platform to run on. Creating such solutions is our domain. We'll help you assess, plan and decide, so your product matches perfectly its intended purpose for years to come. That includes stockpiling parts for extended lifetime of your product, early planning of future migration strategies, and planning variants and scalability to match your growing needs without inflating the costs. All that because business proficiency is a part of a good hardware service.

Agile Full-stack Embedded:

Digital design and prerequisites

From need assessment to iterative PCB design using Agile methodology, our process ensures that every detail is taken into account. We’ll communicate with you and iterate on the project until all your targets and prerequisites are met. By the end of the digital stage of product design you’ll be certain about your new solution, and able to plan your business accordingly.

Prototyping, debug and manufacturing

We manufacture several prototypes, resolve any issues, and implement late-stage amends before moving on to hardware and software testing to prepare for a stable release of the board. Our local facility is equipped to handle mass production, so you can rest assured that your product will be produced with the highest standards of quality and security.

Customize or bring your own

We develop, program, debug and manufacture embedded systems provided by our clients. Bring your product to us on any stage of development, and we’ll deliver a feature-complete working and tested solution. We also offer customization of our products. We fully own their IP, so we can customize them to add or remove interfaces, features and dimensions.

Buy an off-the-shelf product

Our proficiency in product design, development, and prototyping allowed us to create our own line of off-the-shelf products products, designed to fit most client needs and fit most market niches. From low-power SBCs to highly performant multi-core edge compute units, advanced networking features, FPGAs, general-purpose computing and AI/ML acceleration. Pick, choose and customize!

What does our process look like?

Project preparation

We perform need assessment and provide proposals and strategies for handling your use case. We choose main components, like the SoC, establish desired connectivity, form factor, and other features.

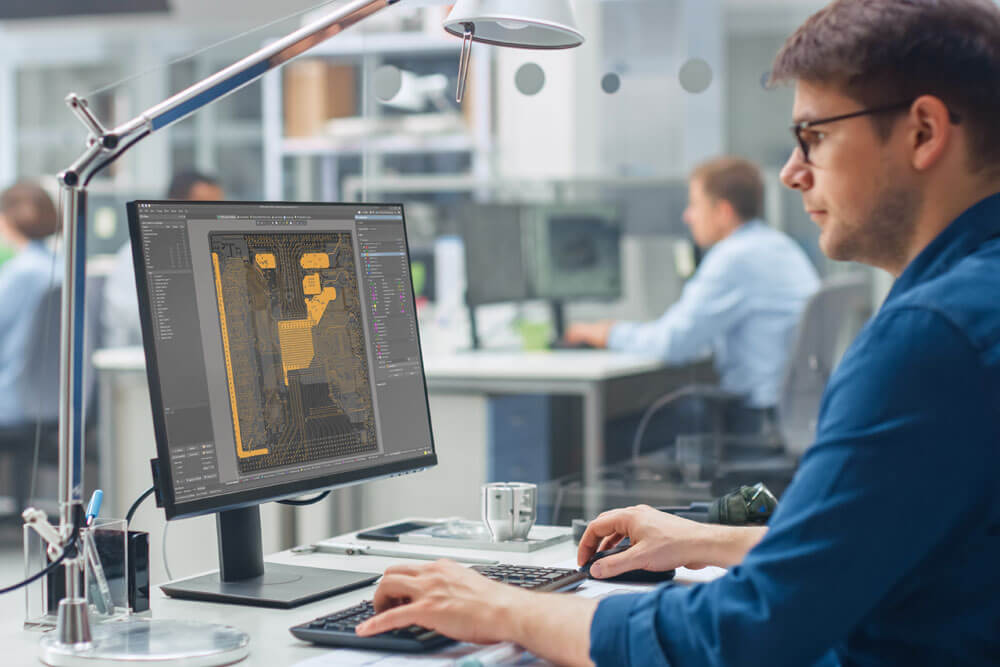

Digital PCB design

Iterative PCB design using Agile methodology, ensuring every detail is taken into account, with back-and-forth communication on features and progress. We prepare a detailed BOM at this stage, including backup strategies for hard-to-obtain parts.

Digital testing and simulation

Testing and digital simulation before prototype production. Your design is reviewed by several electronics and manufacturing engineers in an approve-or-amend loop.

Prototype production

Prototype production run. We order all the parts, and they all go to our local manufacturing facility, where your product is assembled.

Prototype hardware testing

Next comes the testing and debugging phase. We test if the board matches the simulated values of the digital design, and iteratively resolve any problems by producing a batch of prototypes.

Test procedure automation

On larger runs, we prepare a test procedure, including an automated test bench. Every single product goes through it, checking signal integrity, solder quality, eliminating faulty components, and checking for other issues.

Final production run

When all this is done, your final production happens! At this stage, we'll also secure stockpiles on the most crucial elements, or elements needed for increased product longevity - if this was a part of our agreement.

Agile development

Project constraints change to match business analytics and internal decisions. We understand that - that's why we're following the best Agile practices, to counter reality's unpredictability, minimize the risks, and deliver an exceptional hardware product.

Updates and Communication

Good information flow is a key value in modern business. It lets you make decisions right on time, and plan out your actions in advance. That's why we offer multiple channels of communication to keep you updated, like Slack, Jira, regular email updates, Git for version control and bug tracking, and live video calls. We can adapt our communication methods to your company's demands and procedures, to seamlessly integrate with your preferred way of development.

Management and leadership

World-class management. All our managerial staff has hardware and software experience, and they're amongst the most experienced and versatile people in their teams. That guarantees flawless issue prediction in the development process, quality code review, impeccable balancing of the project across the team, task management, and code review. To be a manager with us requires both business and engineering practice. That way we're sure we understand your individual needs and know how to fulfill them. Great management is also a prerequisite for hiring the best engineers. Top talent requires a matching environment.

Norms and certification

Industrial solutions require industrial practices. Whether you're developing for the factory floor, the medical sector, automotive, aerospace, and military - each of these fields require stringent adherence to norms and certifications. We know how important it is to fulfill these requirements - an uncertified product may as well never exist. That's why we put a lot of attention into our procedure compliance. Additionally, our country of origin allows us to cover both European and US markets without any legal hiccups, since we're well under TAA requirements.

Cooperation and billing

Getting your hardware made is one thing, but doing that in a business-friendly manner is another. We pride ourselves in our business-first and client-centric approach to embedded development. Get in touch with us - we'll discuss your individual contract specifics. We offer flexible billing options, including fixed-price and time-and-materials billing, but we're open to negotiating agreements that fit your specific needs or preferences.

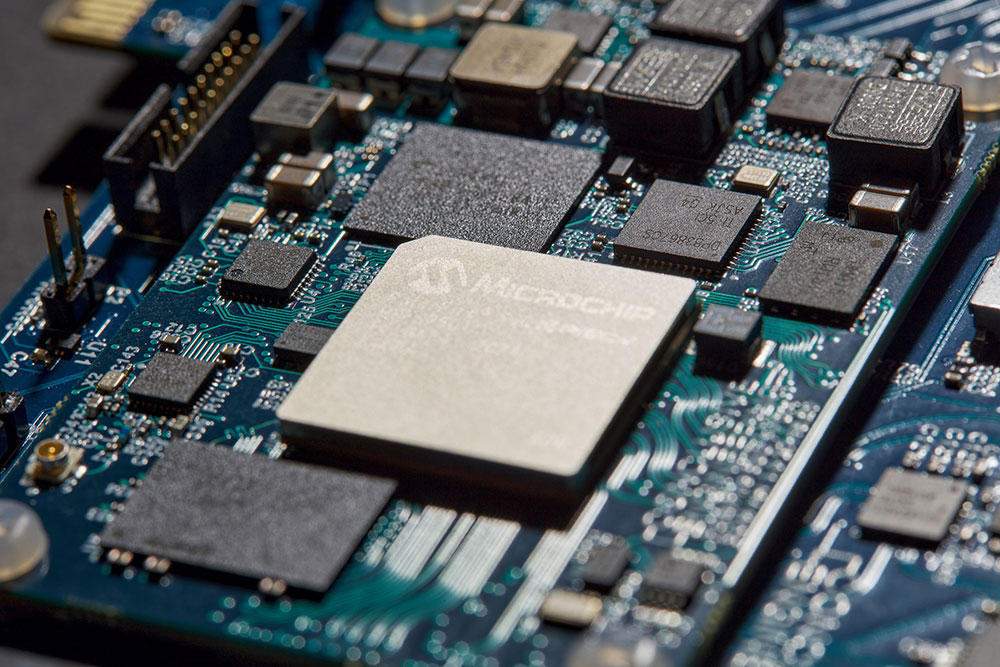

Technologies we use

Our standard hardware designs usually utilize an SoC based on Arm® or RISC-V CPU. The SoC is chosen to match the desired application, and features additional technologies, such as AI/ML accelerators, FPGAs, network traffic processing technologies like DPAA/DPAA2, graphic acceleration, and more.

Additional required pieces of discrete digital logic, appropriate power circuitry and connectors that provide necessary connectivity with the external world - attention to all these elements assure that your new product will fit your application like a glove. Additional required pieces of discrete digital logic, appropriate power circuitry and connectors that provide necessary connectivity with the external world - attention to all these elements assure that your new product will fit your application like a glove.

Cooperation

Let's work on your project together! We can seamlessly integrate with your teams or existing subcontractors, bring in our own management and consulting, supervision, planning, and more! Our flexible forms of cooperation include fixed-price and time-and-material-billing agreements. Hybrid or custom forms of cooperation are available as well.

Get a tailored solution for your project needs – connect with our experts

We would like to understand your project better before we start. We’ll review your project and get back to you.